GM Leitch Forklifts

Published on: 7th October 2020

‘When you’ve spent a lifetime in and around plant, machinery and lorries, you get a feel for what works and, perhaps more importantly, what doesn’t’ says Roderick Chisholm, better known as ‘Tootan’ since he was a toddler. This is why he was given the task of specifying the new truck for GM Leitch Materials Handling, based in Inverness.

Since being established in 1975 by Gordon Leitch; GM Leitch has been working in partnership with Toyota, importing forklifts to the UK. It is also an agent for Manitou equipment for the north of Scotland. It is a family run business, with Gordon Leitch Jr at the helm since 2006.

When Tootan arrived at the company 2 years ago, GM Leitch ran a Euro 5 DAF CF 8×2 rear steer rigid with an Andover Trailers plant body and double-flip ramps at the rear. It was seven years old with 466,000km on the clock. ‘My boss, Gordon, was too busy and told me to go and sort it out,’ he revealed.

Choosing a new chassis was, he admitted, a difficult decision but after plenty of thought he plumped for Volvo, in part because he found them easy to deal with, and the fact the site ran 24 hours a day during the week. ‘I wanted somewhere where we could go in and it not be a problem, the same for parts as well, and Volvo has been excellent,’ he said. ‘We have a five years R&M agreement; they work around us.’ It was the 12.8 litre 540hp engine with a 12 Speed I-Shift Gearbox that Tootan chose to power his 8×2 Rear Steer FH. Delivering 2,600Nm torque, the big engine works lazily, copying easily with the surrounding highlands. Something, he commented, ‘a smaller engine would have to work a lot harder to do’.

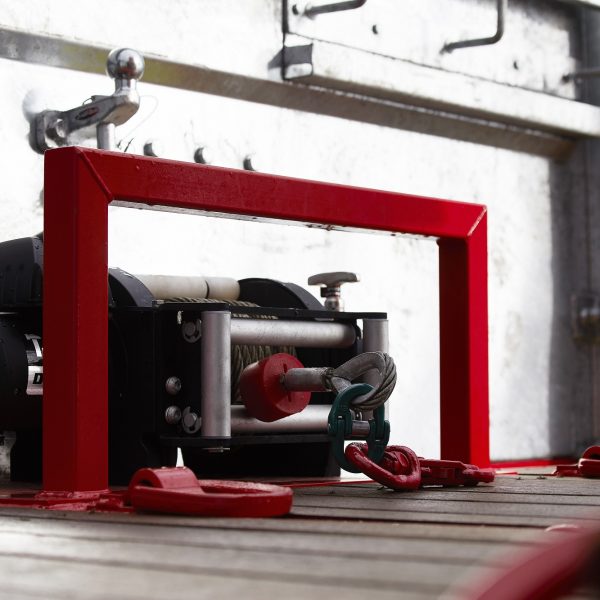

On the bodywork, Tootan pitted Sterling against other suppliers in his search to get the best body on the market. We were very honoured to be his final choice. His reason for his decision was due to our attention to detail. ‘Even the wiring loom is sealed end-to-end, and the pump where the hydraulics are is also sealed, which is what I wanted,’ he said. ‘It was just little things I wanted, and nothing seemed to be a problem.’ Sterling’s Area Sales Manager, Kelvin Carruth thoroughly enjoyed sitting down with Tootan, in a café in Inverness, to spec this body up. They went into a lot of depth, talking through every option on our online configurator, as what he wanted to achieve wasn’t easy. He wanted a swiss army knife of bodies, one that had a flat deck to carry cabins, yet a shallow enough loading angle to load forklifts. The Sterling Cheesewedge Ramp with Centre Trapdoor, was the ramp they decided would be best suited to his requirements. Not only did this offer him the shallowest angle possible with a totally flat deck for cabins, but the gate system allowed him to have a safe working platform for three wheeled forklifts, yet still be able to put an excavator boom through the middle. Tootan’s choice to switch to cheesewedge also gives him better visibility than his current truck, making it a lot easier to drive.

‘The rest of Tootan’s choices resulted in one of the most highly spec’d bodies I have ever sold!’ comments Kelvin, but continues ‘Although one standard feature of the Sterling body that will make a big difference to the life of the truck, is the extensive use of galvanising, this reduces the salt corrosion and rust, which is especially prevalent in the Scottish Highlands.’

We are glad Tootan has the truck of his dreams now, he says that ‘it’s the best job I have ever had’, his new Sterling-bodied Volvo means that he ‘actually enjoys coming to work now’. We are thankful to have the opportunity to make yet another driver happy.